How 3D Printing is Disrupting Manufacturing Industries

3D printing, also known as additive manufacturing, is revolutionizing traditional manufacturing processes with its ability to create complex and customized objects layer by layer. This disruptive technology is transforming various industries, from automotive and aerospace to healthcare and consumer goods. Companies are embracing 3D printing to reduce production costs, accelerate product development, and customize products for individual customers. As a result, traditional manufacturing methods are being challenged by the innovative capabilities of 3D printing, leading to a significant shift in the industry landscape.

1. Introduction to 3D Printing

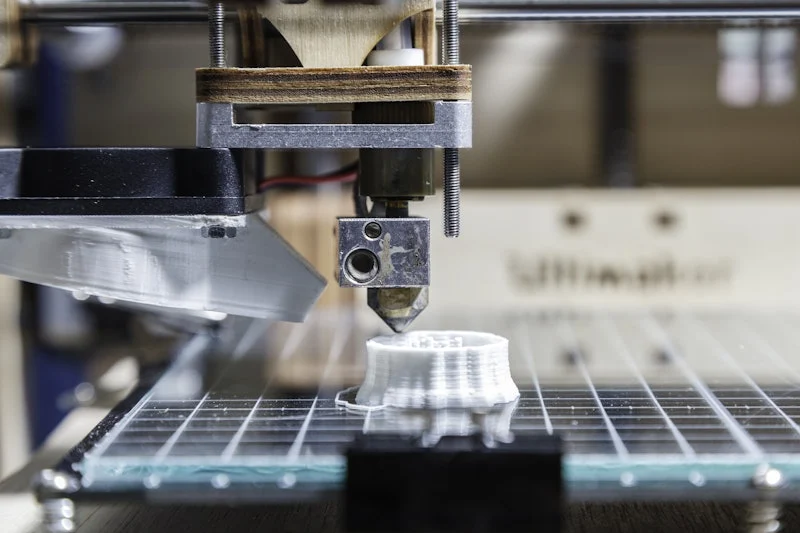

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. This innovative technology involves layering materials such as plastic, metal, or resin to build objects layer by layer. 3D printing has gained popularity in various industries due to its ability to create complex shapes and designs that are difficult or impossible to produce with traditional manufacturing methods.

With the advancements in 3D printing technology, the cost of 3D printers has decreased, making it more accessible to businesses and individuals. This has led to significant advancements in the manufacturing industry, disrupting traditional production processes and opening up new possibilities for design and customization.

2. Impact on Customization and Design

One of the key advantages of 3D printing is its ability to enable customization and intricate design possibilities. Traditional manufacturing processes often involve significant tooling and setup costs, making it challenging and expensive to produce custom or complex designs. With 3D printing, intricate and customized designs can be created without the need for expensive tooling, allowing for greater design freedom and flexibility.

This has led to the rise of personalized products in various industries, from custom medical implants to bespoke consumer goods. 3D printing has also enabled rapid prototyping, allowing designers and engineers to quickly iterate and test designs, accelerating the product development process.

3. Disruption in the Automotive Industry

The automotive industry has been significantly disrupted by 3D printing technology. 3D printing has been used to produce prototype parts, customized components, and even entire vehicles. This has streamlined the prototyping and manufacturing processes, reducing lead times and costs associated with traditional manufacturing methods.

Furthermore, 3D printing has enabled the production of lightweight and complex geometries that were previously unattainable with traditional manufacturing techniques. This has led to advancements in vehicle performance, fuel efficiency, and design aesthetics, driving innovation within the automotive sector.

4. Evolution in Aerospace Manufacturing

3D printing has revolutionized the aerospace industry by offering a more efficient way to produce complex aircraft components. The ability to create lightweight yet durable parts using 3D printing has led to significant advancements in aircraft design and performance. This technology has also facilitated the production of spare parts on-demand, reducing inventory costs and lead times for maintenance and repairs.

Additionally, 3D printing has enabled the development of novel aerospace components that were previously unattainable with traditional manufacturing methods. This has led to improved fuel efficiency, reduced emissions, and enhanced overall aircraft safety and performance.

5. Impact on Healthcare and Medical Devices

3D printing has had a profound impact on the healthcare industry, particularly in the production of custom medical devices and implants. This technology has enabled the creation of patient-specific implants, prosthetics, and surgical guides, improving patient outcomes and reducing surgical risks. 3D printing has also facilitated the rapid prototyping of medical devices, allowing for iterative design improvements and accelerated product development.

Furthermore, 3D printing has made it possible to create anatomical models for surgical planning and medical training, providing surgeons with valuable tools for preoperative visualization and practice. The customization and on-demand production capabilities of 3D printing have transformed the medical device industry, offering tailored solutions for patients and healthcare professionals.

6. Disruption in Consumer Goods and Electronics

3D printing has disrupted the consumer goods and electronics industries by enabling the production of customized and on-demand products. From personalized smartphone cases to custom jewelry, 3D printing has empowered consumers to create unique and tailored products according to their preferences. This shift towards personalized manufacturing has challenged traditional mass production models, allowing for more diverse and niche product offerings.

Additionally, 3D printing has facilitated the rapid prototyping and production of electronic components, leading to faster innovation cycles and product development. This technology has also been utilized to create lightweight and complex designs for electronic devices, driving advancements in product performance and aesthetics.

7. Advancements in Industrial Manufacturing

3D printing has brought significant advancements to industrial manufacturing processes, particularly in the production of tooling, jigs, and fixtures. This technology has enabled the rapid and cost-effective production of custom tooling solutions, reducing lead times and enhancing manufacturing flexibility. Additionally, 3D printing has streamlined the production of complex and low-volume components, offering a more efficient alternative to traditional manufacturing methods.

Furthermore, 3D printing has facilitated the development of sustainable manufacturing practices by minimizing material waste and optimizing part geometries for lightweighting. This has led to improvements in resource efficiency and environmental impact within the industrial manufacturing sector.

8. Impact on Supply Chain and Logistics

3D printing has the potential to disrupt traditional supply chain and logistics models by enabling on-demand and localized production. This technology has the capability to reduce lead times, transportation costs, and inventory requirements by producing goods closer to the point of consumption. By decentralizing production, 3D printing can offer greater agility and responsiveness to market demands, particularly for customized and low-volume products.

Additionally, 3D printing has the potential to transform spare parts management and distribution, allowing for digital inventories and on-demand production of replacement components. This could significantly reduce the reliance on physical warehouses and global distribution networks, offering a more sustainable and resilient approach to supply chain management.

9. Implications for Intellectual Property and Licensing

The rise of 3D printing has raised important implications for intellectual property (IP) rights and licensing agreements. The ease of reproducing physical objects through 3D printing has led to concerns about copyright infringement and unauthorized replication of patented designs. This has prompted discussions around the enforcement of IP laws and the development of new licensing models to accommodate the digital manufacturing landscape.

Furthermore, 3D printing has challenged traditional notions of product ownership and distribution, particularly with the potential for decentralized and individualized production. This has prompted debates about the future of licensing, distribution channels, and digital rights management in the context of 3D printed goods.

10. Future Outlook and Potential Challenges

The future of 3D printing in manufacturing holds great promise, with continued advancements in materials, technology, and applications. As 3D printing becomes more integrated into traditional manufacturing processes, it has the potential to drive further innovation, sustainability, and customization across industries. However, there are challenges to address, such as quality control, material limitations, and regulatory considerations, which will require ongoing attention as 3D printing continues to disrupt and transform the manufacturing landscape.

Overall, the disruptive impact of 3D printing on manufacturing industries is undeniable, reshaping the way products are designed, produced, and distributed. As the technology continues to evolve, its potential to drive innovation and create new opportunities for businesses and consumers alike is expected to grow, shaping the future of modern manufacturing.

| Industry | Disruption |

|---|---|

| Automotive | 3D printing allows for rapid prototyping and customization of car parts, leading to reduced production time and costs. |

| Aerospace | Manufacturing complex and lightweight aircraft components is made easier with 3D printing, enabling design freedom and fuel efficiency. |

| Healthcare | Custom implants, prosthetics, and medical devices can be produced with 3D printing, improving patient care and treatment outcomes. |

| Fashion | Designers can create unique and intricate clothing, shoes, and accessories using 3D printing, challenging traditional production methods. |

3D printing is revolutionizing various manufacturing industries by enabling faster prototyping, customized production, complex designs, and cost-effective manufacturing. This disruptive technology is reshaping traditional manufacturing processes and opening up new possibilities for innovation and creativity across different sectors.